1. Product Overview

Fiberglass Wire Mesh is a composite grid material woven from high-strength alkali-free glass fiber (E-Glass) and coated with PVC/polyester resin, combining the corrosion resistance of fiberglass with the structural strength of metal wire. Through specialized manufacturing processes, glass fiber yarn is coated with weather-resistant material and reinforced with high-tensile metal wires (e.g., stainless steel or galvanized steel), resulting in a lightweight, high-strength, and aging-resistant composite mesh.

Core Value Proposition: A superior alternative to traditional metal wire mesh, addressing issues like rust, heavy weight, and complex installation, ideal for long-term protection and filtration in harsh environments.

2. Material & Structure

Component Technical Specifications

Base Material Alkali-free glass fiber yarn (E-Glass, SiO₂ content ≥72%), diameter 0.08mm–0.25mm, tensile strength ≥2000MPa

Reinforcement Frame 304 stainless steel/galvanized steel wires (diameter 0.3mm–1.2mm), interwoven to form a support grid

Coating Dual-layer PVC or polyester resin (thickness 0.15mm–0.3mm), with UV-resistant, flame-retardant, and anti-static additives

Weaving Process Plain/twill weave, fused nodal reinforcement, edges sealed with silicone or heat treatment

3. Technical Specifications

Parameter Specifications

Mesh Size 3mm×3mm – 50mm×50mm (square/diamond apertures, tolerance ±5%)

Width 1m – 4m (customizable splicing, max continuous length 100m)

Wire Diameter Glass fiber: 0.1mm–0.5mm; Metal wire: 0.3mm–1.5mm

Tensile Strength Longitudinal ≥2500N/5cm, Transverse ≥1800N/5cm (ASTM D5035 standard)

Temperature Range -50°C to +260°C (short-term heat resistance up to 300°C, no deformation)

Corrosion Resistance Passes ISO 9227 salt spray test ≥2000 hours, no rust or coating delamination

Flame Retardancy UL94 V-0 (self-extinguishing within <10 seconds)

Surface Resistance 10³–10⁶Ω (anti-static coating optional, compliant with ATEX explosion-proof standards)

4. Key Applications

Industrial Filtration:

Petrochemicals: Catalyst filtration, gas separation screens (acid/alkali resistance, explosion-proof).

Power Plants: Flue gas dust removal, desulfurization tower filters (high-temperature & sulfur corrosion resistance).

Construction Protection:

Curtain Wall Reinforcement: Replaces metal mesh for GRC wall crack prevention, reducing structural load.

Underground Engineering: Moisture-proof ventilation layers for tunnels and utility tunnels.

Transportation:

Ship deck anti-slip mesh, aircraft cargo compartment partitions (lightweight, salt spray resistance).

Specialized Uses:

Nuclear facility radiation shielding, high-temperature kiln insulation curtains (radiation/instant heat resistance).

5. Core Advantages

Lightweight & High Strength: 1/4 the weight of stainless steel mesh with 30% higher strength, reducing transport and installation costs.

Extended Lifespan: ≥15 years outdoors (vs. 3-5 years for metal mesh), lowering lifecycle costs by 50%.

Environmental Adaptability:

UV resistance (≥90% UV blocking), acid/alkali resistance (pH 2–12), mold-proof (ASTM G21 compliant).

Stable performance from polar to equatorial climates.

Safety Compliance: RoHS, REACH, and CE certified, meeting EU industrial material standards.

6. Customization Services

Functional Upgrades: Anti-static coating, fluorescent marker lines, magnetic edges (for automated installation).

Flexible Sizing: Custom cuts, roll/sheet packaging, pre-installed hooks or flanged frames.

Fast Delivery: Standard specs in 7 days, samples available (MOQ 50m²).

7. Competitive Comparison

Feature Fiberglass Wire Mesh Traditional Stainless Mesh Standard Plastic Mesh

Weight 0.8–1.2kg/m² 3.5–5kg/m² 0.5kg/m² (low strength)

Corrosion Resistance No rust after 2000h salt spray Pitting after 500h Prone to aging/cracking

Installation Cut-to-fit, no welding Welding required Frequent replacement needed

Lifecycle Cost $15/m²·year (15-year lifespan) $30/m²·year (5-year lifespan) $20/m²·year (2-year lifespan)

8. Quality Assurance

Test Reports: Full SGS certification (tensile strength, flame retardancy, eco-compliance).

| Mesh size |

5x5 mesh, 5x4 mesh, 4x4 mesh, 3x3 mesh, 2.5x2.5 mesh, 1x1 mesh |

| Weight/square meter |

60g-300g |

| Each roll length |

10m, 20m, 30m, 50m-300m |

| Width |

0.5m-2m |

| Example of applications |

1).75g / m2 mesh fabric used in the reinforcement of thin slurry, to eliminate small cracks and scattered throughout the surface pressure.

2).110g / m2 mesh cloth is widely used in indoor and outdoor walls, prevent the various materials (such as brick, light wood, prefabricated structure) of treatment or caused by a variety of expansion coefficient of wall crack and break .

3). 145g/m2 mesh fabric used in the wall and be mixed in various materials (such as brick, light wood, prefabricated structures), to prevent cracking the scatter

and whole surface pressure, especially in the external wall insulation system (EIFS ).

4). 160g / m2 mesh fabric used in insulator layer of reinforcement in the mortar, through shrinkage and temperature changes by providinga space to movement

maintain between the layers,prevent crack and rupture due or temperature change.

|

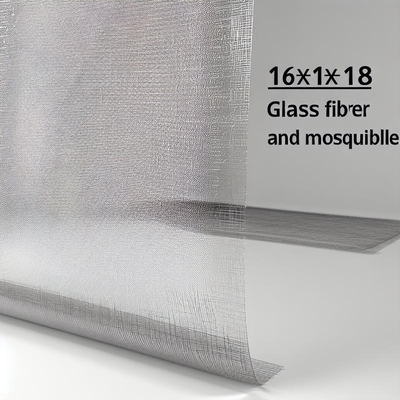

| Mesh size |

16x16 mesh, 15x14 mesh, 12x12 mesh, 10x10 mesh, 9x9mesh, 8x8 mesh,

6x6 mesh

|

| Weight/square meter |

40g-120g |

| Each roll length |

10m, 20m, 30m, 50m-300m |

| Width |

0.05m-2m |

| Packing |

carton |

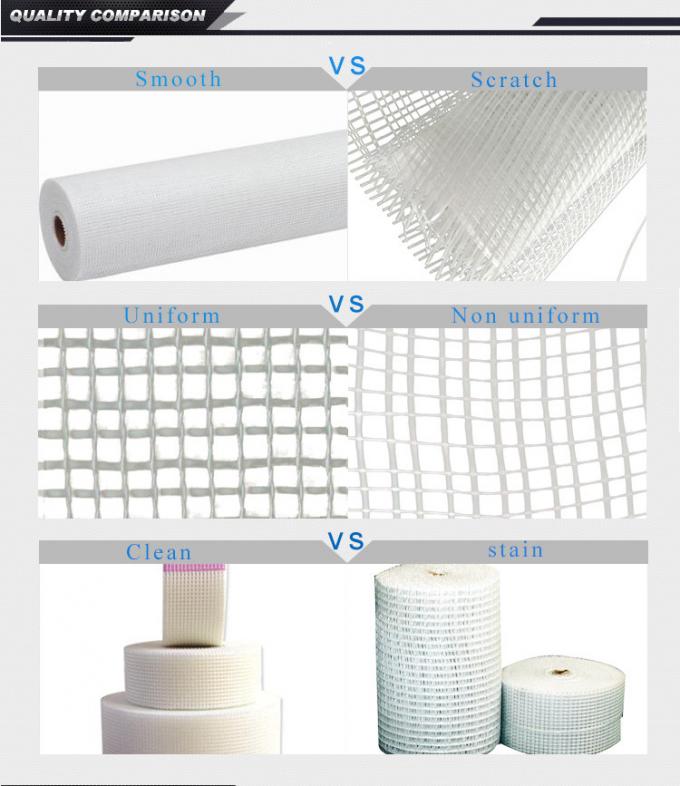

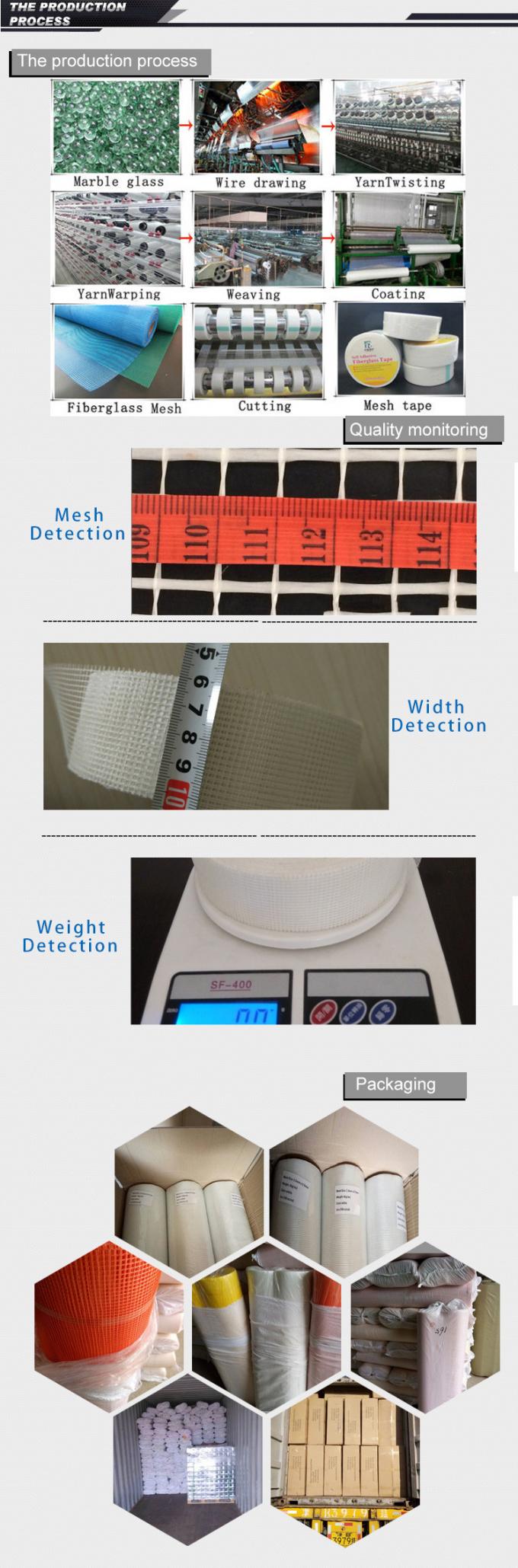

Hongye is home to a range of wire mesh products dedicated to providing online sales and service, where you can find almost all the related products. Some of the products are manufactured by our factory in Anping (since 1995) and some by our partner factories. All the products have been tested strictly before sales.

Hongye is proud of the people that work for us,the experienced workers, strict inspectors and energetic sales, whose work guarantees the best price, quality products and reliable service for customers.

Hongye is always ready to be your one-stop supermarket for wire mesh.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!